What is SCADA System?

SCADA stands for Supervisory Control and Data Acquisition. It is a computer system application to monitor and control plant operations as well as processes in industries. SCADA is a system for gathering and analyzing real-time data. Power generation and distribution, telecommunication or manufacturing plants usually use this system.

How SCADA System Works

SCADA application is important in industrial applications since it helps maintain efficiency, process data for a smarter and faster decision, and communicate system issues to help minimize downtime.

The system gathers all the data from sensors and instruments located in remote areas. The computer process this data and presents it in a timely manner. The information is all gathered together and transferred back to the system while giving alerts that an error has occurred. The system is displaying all the information and error in a logical and organized fashion.

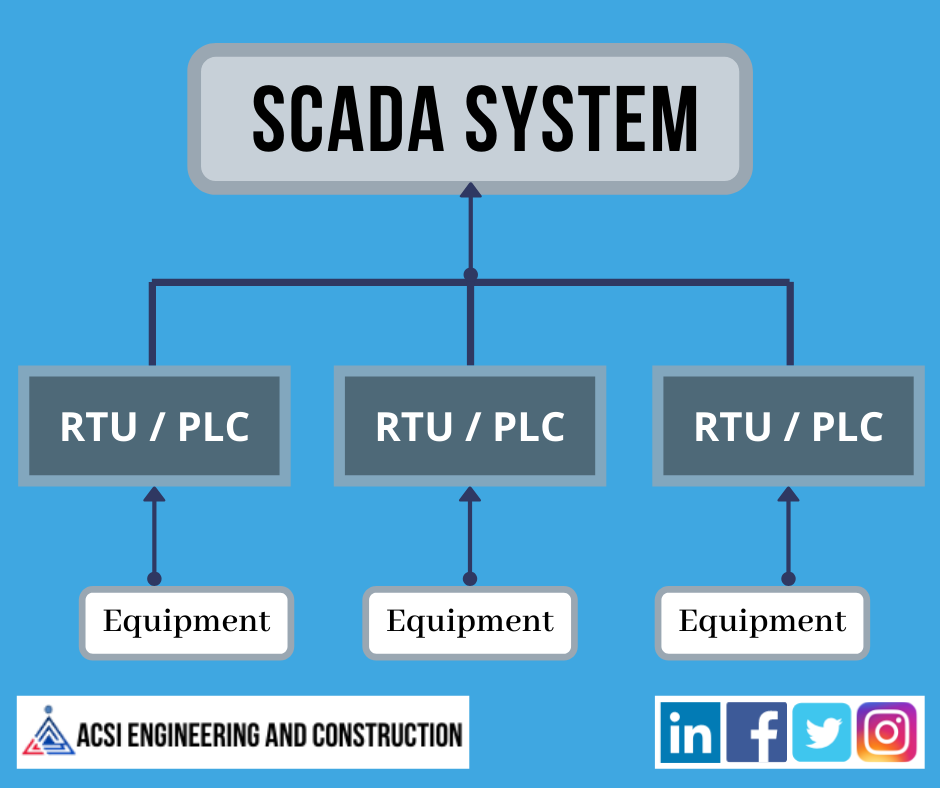

SCADA software application shows an overview of how each area in the plant is performing. The structural design of a standard SCADA system starts with Remote Terminal Units (RTU) and/or Programmable Logic Controllers (PLC). Signals are sent through the remote terminal unit (RTU) and programmable logic controllers (PLC). The system takes all the data and enables alarm status. Following, allowing operators and maintenance personnel to promptly take action if there are plant problems.

An operator can run the system virtually. Furthermore, allowing the operator to keep track of the entire process from his place or control room. Also within SCADA software is the ability to log data for the historical purposes of the system. Because of the current SCADA software, a historical collection of data is available to further improve plant processes.